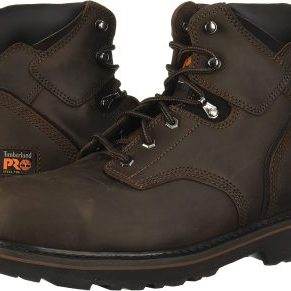

| Product Type | Insulated work boots |

| Product Size | 36~48 |

| Season | Spring, Autumn |

| Material | Pu, rubber ,EVA,Tpr |

| Color | Black, blue, coffee, dark gray, dark |

| Function | Anti-Impact, Anti-Slip, Electrical Insulation |

| Gender | Men, Women, Unisex |

| Size | 36~48 |

| Color | Black or customized |

| Logo | Toprise or customized |

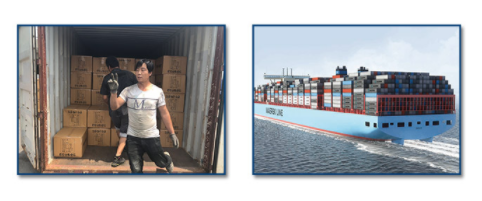

| Packing | One pair per box, 50 pairs per large carton |

| Delivery | 40-90 work days |

| MOQ | sample 1PC , support customized logo for 50 PCS |

| Payment Terms | Paypal . TT. Trade Assurance |

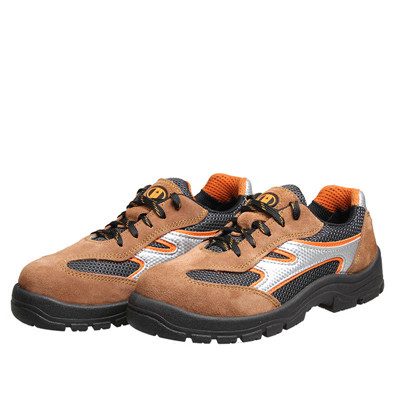

| Feature | Fashionable and lightweight outdoor, non-slip wear-resistant insulation |

The difference between insulated work boots and anti-static shoes

1. Use environment:

Anti-static shoes: suitable for pharmaceutical factories, food factories, clean workshops of electronics factories, laboratories, etc. It is a kind of work shoes worn by the production workshops and advanced laboratories of the microelectronics industry to reduce or eliminate the hazards of static electricity.

Insulated work boots: Electrically insulated leather shoes and cloth-covered electrical insulated shoes with a test voltage of 15KV or less, used in working environments of power frequency (50-60F) below 1000V, and electrically insulated work shoes in test electrical cities above 15KV, suitable for industrial In an operating environment with a frequency above 1000V.

In general: insulated work boots can withstand much higher voltage than anti-static shoes.

2. Working principle:

Anti-static shoes: There is anti-static EVA in the middle of the sole, which can derive the static charge of the human body. The shoes do not precipitate dust. The human body is isolated from the earth through this shoe, so that even if the human body is in contact with a conductive body, it will not cause electricity to enter the ground through the body. accident. Functionally, anti-static shoes can prevent electric shocks below 250V.

Insulating work boots: Use insulating materials to seal the charged body, thereby isolating the charged body or conductors of different potentials, so that the current can flow according to a certain path. It can also play a role in heat dissipation and cooling, mechanical support and fixation, and protection of conductors.

3. Shoe structure:

Anti-static shoes: high-quality PU leather (ISO9001 certification) environmentally friendly PU material, PU anti-static slippers use static dissipative material PU (polyurethane) to make the soles.

Insulated work boots: The thickness of the outsole of the insulated work boots shall not be less than 4 mm. When the pattern cannot be measured, the thickness shall not be less than 6 mm. The wear scar length of the outsole of insulating leather shoes should not be greater than 10mm; the wear loss of electrically insulating cloth-top shoes should not be greater than 1.4cm3; the wear loss of 15kv and lower electrically insulating work boots should not be greater than 1.0cm3; the wear loss of electrical insulating work boots of 20kv and above The abrasion loss is not more than 1.9cm3.